History

HOW IT ALL STARTED

On March 25, 1865, the coppersmith Franz Krull rented a coppersmith’s workshop in Narva well-equipped for that time - a wooden house with five rooms, two kitchens and three basements, and a garden and several outbuildings. With the help of a couple of workers, he began to manufacture a variety of equipment for sugar, beer, coffee, and other factories and pharmaceutical laboratories. Over the next five years, the proceeds from equipment sold mainly to distilleries in St. Petersburg, Novgorod, Pskov, Olonets, and Estonia eventually allowed Krull to buy the workshop. Krull became famous throughout Russia with the first modern vodka distillation apparatus built in 1870, which was more productive, more economical.

On March 25, 1865, the coppersmith Franz Krull rented a coppersmith’s workshop in Narva well-equipped for that time - a wooden house with five rooms, two kitchens and three basements, and a garden and several outbuildings. With the help of a couple of workers, he began to manufacture a variety of equipment for sugar, beer, coffee, and other factories and pharmaceutical laboratories. Over the next five years, the proceeds from equipment sold mainly to distilleries in St. Petersburg, Novgorod, Pskov, Olonets, and Estonia eventually allowed Krull to buy the workshop. Krull became famous throughout Russia with the first modern vodka distillation apparatus built in 1870, which was more productive, more economical.

ENLARGEMENT

In 1875, Krull sold the Narva workshop and bought a plot of land on Paldiski Road in Tallinn, where he built a small factory and employed 14 people. After the death of old Krull in 1899, his sons built a large modern factory with 12 spacious production buildings, an office, and a residential building on the current location of TMT on Kopli Street. In 1901, there were already 250 employees.

MAIN PRODUCTION ARTICLES

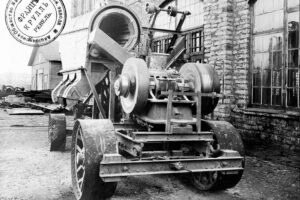

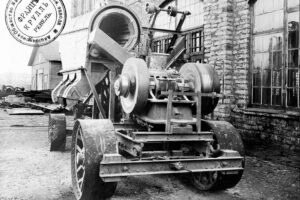

In 1905, Russia was the first to produce refrigeration equipment, which was sold to state-owned companies, warships and merchant ships, and forts. Steam boilers, pumps, and woodworking equipment were also manufactured. In the 1920s, in connection with Estonia's independence, the manufacture of various consumer goods was launched: cast iron stove rings, dampers, oven doors, cast iron pots, bench legs, grave crosses, etc. Agricultural machinery was also produced: grain sorters, ploughs, hay meal machines, horse rake, spring carts, potato harvesters, animal feed steamers, peat machines, and dairy boilers. Many awards were received at exhibitions both in Estonia and in Moscow, including the highest award - the Grand Prix for the collection of cast iron and metal works. In 1929-1940, large steam boilers were manufactured for Estonian power plants, central heating boilers for both industrial and residential buildings, road rollers, gravel sorters, wide and narrow-gauge locomotives, motor locomotives, equipment for the oil shale industry, and the cold storage of the Port of Tallinn. Orders also came from India, Iran, England, Yugoslavia, Romania, and Bulgaria.

IN THE COMPOSITION OF RUSSIA

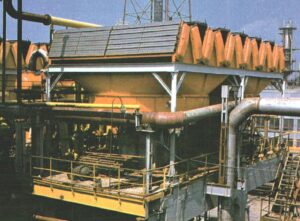

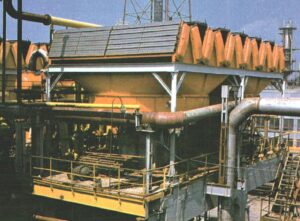

In 1941 the factory was evacuated: all equipment, 357 workers, 153 railway platforms, and six coaches. The destination was Kuibyshev. One echelon was directed to the city of Yegoryevsky in the Moscow region; the last echelon left Tallinn on July 7, 1941 and passed through Kuibyshev in the city of Kiselevsky in the Altai Krai. The equipment was taken to the city, to the repair shops of the mine. Later, a new factory was built, where production began in 1942, although repair work initially accounted for 50% of the total workload. As the plant had a unique profile throughout the former Soviet Union, it was transferred to all-Union subordination - on June 5, 1945; it was renamed the State Union Factory No. 9. In 1949, the plant became part of the former USSR Ministry of Oil Industry system and was renamed Tallinn Machinery Plant. From 1945 to 1963, the plant produced various equipment and mechanisms for the oil shale and gas industry and oil refining companies: fans, centrifugal pumps, paraffin-making machines, truck tanks, conveyors, elevators, oil rigs sold to Azerbaijan, Albania, Romania, and China. Trailer houses and steam boilers special for the dairy industry were also produced, and even ultrasonic devices and unique devices were commissioned by the Academy of Sciences. In 1963, the first in the former USSR, the plant began production of air coolers, the nomenclature of which was constantly expanding. TMT (then Tallinn Machinery Plant named after Lauristin) was known throughout the former USSR for its high-quality products.

AFTER REGAINING INDEPENDENCE

In 1993, the company was privatized and went through a deep period of decline. In the late 1990s, the share of eastern markets declined significantly due to the 1997 economic crisis in Russia. Opportunities were sought to sell products to the home country, and manholes, Finnish sauna stoves, metal construction, garden gates, containers, and even wooden garden benches were manufactured. From the end of 2000, the company began with radical changes to modernize. TMT again focused on the production of air coolers and larger orders.

On March 25, 1865, the coppersmith Franz Krull rented a coppersmith’s workshop in Narva well-equipped for that time - a wooden house with five rooms, two kitchens and three basements, and a garden and several outbuildings. With the help of a couple of workers, he began to manufacture a variety of equipment for sugar, beer, coffee, and other factories and pharmaceutical laboratories. Over the next five years, the proceeds from equipment sold mainly to distilleries in St. Petersburg, Novgorod, Pskov, Olonets, and Estonia eventually allowed Krull to buy the workshop. Krull became famous throughout Russia with the first modern vodka distillation apparatus built in 1870, which was more productive, more economical.

On March 25, 1865, the coppersmith Franz Krull rented a coppersmith’s workshop in Narva well-equipped for that time - a wooden house with five rooms, two kitchens and three basements, and a garden and several outbuildings. With the help of a couple of workers, he began to manufacture a variety of equipment for sugar, beer, coffee, and other factories and pharmaceutical laboratories. Over the next five years, the proceeds from equipment sold mainly to distilleries in St. Petersburg, Novgorod, Pskov, Olonets, and Estonia eventually allowed Krull to buy the workshop. Krull became famous throughout Russia with the first modern vodka distillation apparatus built in 1870, which was more productive, more economical.