www.tmt.ee websites use cookies. A cookie is a piece of information that a website transfers to the cookie file on your computer.

There are two types of cookies:

- Persistent cookies remains permanently on the cookie file of your computer. They may used, for example, to recognize that you are a returning visitor to the site and adapt the website's content to fit your needs or to collect statistical data.

- Session cookies are temporary and will disappear when you exit the website or close your browser. Session cookies may be used in order to enable certain site functions such as applying for checkout or log in.

Cookies are commonly used on our websites to facilitate better user experience. Cookies enable our web servers to recognize you and automatically adapt the content to fit your needs when you access the site. Using cookies also makes it easier for us to learn about our users' needs. They provide us with usage statistics which enable us to measure and improve our website's performance.

Our cookies can be created by different providers that help us to deliver our web services. An example of such providers are Google, Facebook, Instagram.

Users of our websites are deemed to consent to the usage of cookies if their web browser is set to accept cookies. If you do not accept cookies, the operation of a number of our website's services and functions may be restricted, for example in being able to retain your personal settings.

You can always choose whether you want to accept cookies in your web browser. If you do not want to accept cookies, you can set your browser to automatically disable them, or to inform you on each occasion when a website is requesting to add a cookie. Please refer to your web browser’s help function to make the necessary settings.

These provisions may be changed from time to time without notice in order for us to be compliant with the legislation and/or generally accepted practice relating to cookies.

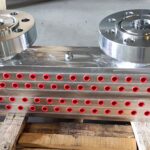

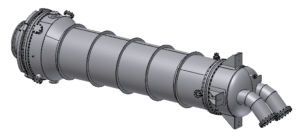

Tallinn Machinebuilding Factory (TMT) has gained several years' worth of experience in the design and manufacture of various vessels, as well as heat-exchange equipment with the use of superaustenitic chrome-nickel steels. The widespread use of such steels in the chemical, oil and gas, cellulose, and medical industries is accounted for their increased corrosion resistance in strong aggressive environments, as well as the resistance to pitting, crevice and intergranular corrosion. Depending on specific operating conditions and customer requirements, the TMT factory offers heat exchange equipment made of the 1.4563; AISI 904L; Sanicro 28; Uranus 28, Alloy 28, Incoloy 800 steels, with chromium content in some of them of up to 27% and nickel content of up to 35%.

Tallinn Machinebuilding Factory (TMT) has gained several years' worth of experience in the design and manufacture of various vessels, as well as heat-exchange equipment with the use of superaustenitic chrome-nickel steels. The widespread use of such steels in the chemical, oil and gas, cellulose, and medical industries is accounted for their increased corrosion resistance in strong aggressive environments, as well as the resistance to pitting, crevice and intergranular corrosion. Depending on specific operating conditions and customer requirements, the TMT factory offers heat exchange equipment made of the 1.4563; AISI 904L; Sanicro 28; Uranus 28, Alloy 28, Incoloy 800 steels, with chromium content in some of them of up to 27% and nickel content of up to 35%. The heat-exchange equipment made of duplex and super duplex steels is used in conditions demanding increased mechanical strength, resistance to aggressive environments and sea water. The TMT factory has mastered the production of multi-purpose heat exchangers and vessels, pipelines and pump parts made of the Duplex 2205 steel, as well as the Super Duplex 2507 steel, which are widely used for equipment designed for the chemical and petrochemical industries. An important reason for the widespread use of the duplex steels is their relatively low cost in comparison with superaustenitic steels due to lower content of scarce nickel.

The heat-exchange equipment made of duplex and super duplex steels is used in conditions demanding increased mechanical strength, resistance to aggressive environments and sea water. The TMT factory has mastered the production of multi-purpose heat exchangers and vessels, pipelines and pump parts made of the Duplex 2205 steel, as well as the Super Duplex 2507 steel, which are widely used for equipment designed for the chemical and petrochemical industries. An important reason for the widespread use of the duplex steels is their relatively low cost in comparison with superaustenitic steels due to lower content of scarce nickel. In collaboration with specialized research institutions and laboratories, the TMT factory is ready to participate in determining the type of material used in designed equipment to ensure its reliable and durable operation.

In collaboration with specialized research institutions and laboratories, the TMT factory is ready to participate in determining the type of material used in designed equipment to ensure its reliable and durable operation.