www.tmt.ee websites use cookies. A cookie is a piece of information that a website transfers to the cookie file on your computer.

There are two types of cookies:

- Persistent cookies remains permanently on the cookie file of your computer. They may used, for example, to recognize that you are a returning visitor to the site and adapt the website's content to fit your needs or to collect statistical data.

- Session cookies are temporary and will disappear when you exit the website or close your browser. Session cookies may be used in order to enable certain site functions such as applying for checkout or log in.

Cookies are commonly used on our websites to facilitate better user experience. Cookies enable our web servers to recognize you and automatically adapt the content to fit your needs when you access the site. Using cookies also makes it easier for us to learn about our users' needs. They provide us with usage statistics which enable us to measure and improve our website's performance.

Our cookies can be created by different providers that help us to deliver our web services. An example of such providers are Google, Facebook, Instagram.

Users of our websites are deemed to consent to the usage of cookies if their web browser is set to accept cookies. If you do not accept cookies, the operation of a number of our website's services and functions may be restricted, for example in being able to retain your personal settings.

You can always choose whether you want to accept cookies in your web browser. If you do not want to accept cookies, you can set your browser to automatically disable them, or to inform you on each occasion when a website is requesting to add a cookie. Please refer to your web browser’s help function to make the necessary settings.

These provisions may be changed from time to time without notice in order for us to be compliant with the legislation and/or generally accepted practice relating to cookies.

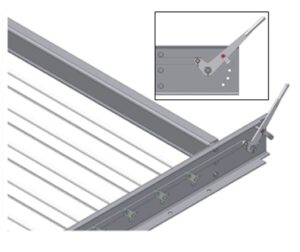

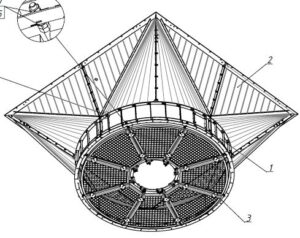

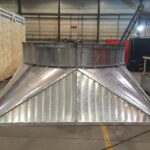

Tallinn Machinebuilding Factory (TMT) supplies heat exchange pipes of various types, both as constituent parts of air cooler units and other equipment with this part in their design.

Fin pipes offered by TMT have the following advantages: high heat transfer coefficient, manufacturing quality, as well as mechanical strength achieved by the technology of finning bimetallic pipes by the knurling method. In addition to these advantages, the pipes are well protected against weather-induced corrosion thus ensuring a long service life even in the most unfavourable climatological conditions.

Tallinn Machinebuilding Factory (TMT) supplies heat exchange pipes of various types, both as constituent parts of air cooler units and other equipment with this part in their design.

Fin pipes offered by TMT have the following advantages: high heat transfer coefficient, manufacturing quality, as well as mechanical strength achieved by the technology of finning bimetallic pipes by the knurling method. In addition to these advantages, the pipes are well protected against weather-induced corrosion thus ensuring a long service life even in the most unfavourable climatological conditions.